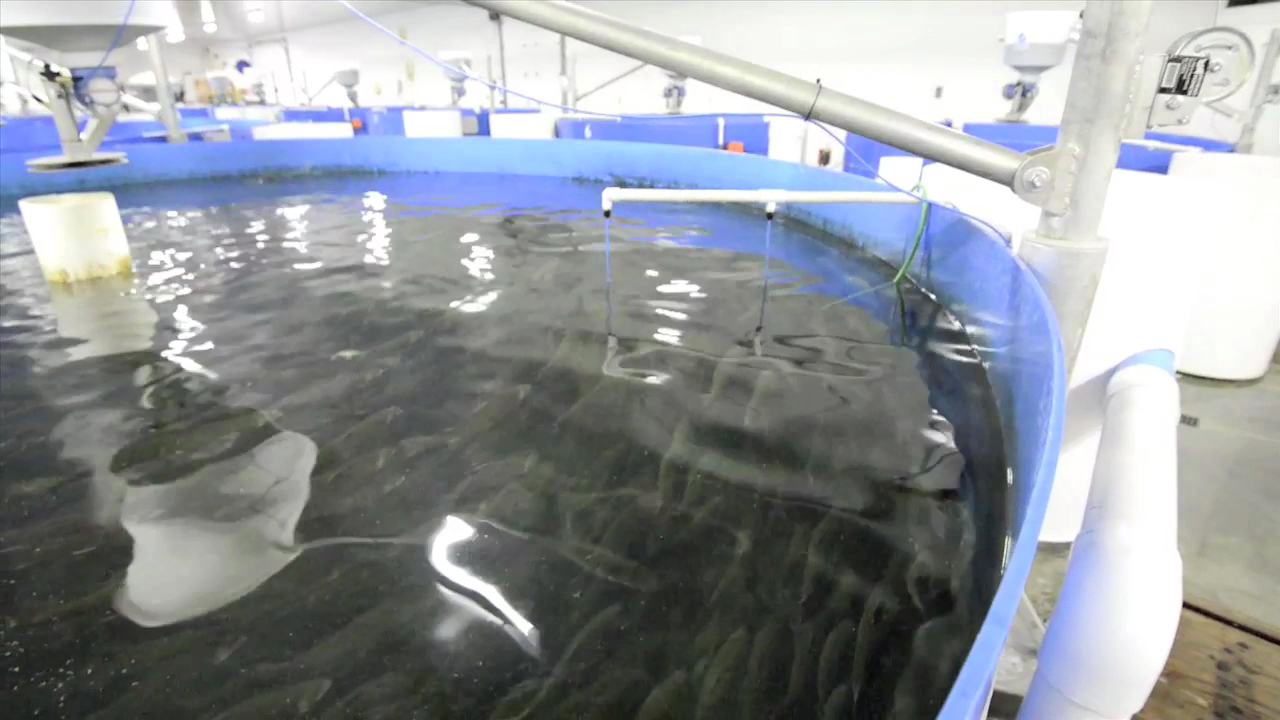

The aquaculture facility is housed in an 8000 sq. ft. concrete building giving complete control of the environment. The foundation of the farm is we draw cold water from a pathogen free aquifer. Since we have a disease free environment, we operate without hormones, antibiotics, vaccines, or any medications. Our strongest treatment is salt water to help resist opportunistic disease. Fish are cultured in polypropylene tanks. Water retention time is one hour. Before it is discharged into the Okanagan River, water enters our state of the art, 450 cubic meter water cleaning plant.

Our facility utilizes state of the art systems to insure consistent water quality and temperatures. Our electronic feeding system maintains near perfect distribution and portioning. We employ custom electronic systems to control CO2 levels and maintain oxygen within precise parameters. Dozens of water conditions are monitored and alarms alert us of any conditions that could jeopardize fish health.

Biosecurity is maintained after obtaining healthy stock and optimizing their health and immunity through good husbandry and health management plans. Eggs are purchased from a broodstock farm with a DFO health certification. Since we have a disease-free environment, we operate chemical-free. While the eggs hatch in 7*C flowing water, meticulous care is taken to keep shells and culls picked and trays clean. As the hatchlings grow, they are sorted by size to gain optimum feed consumption.

Record keeping plays an important role in fish health and farm profitability. Feed consumption, water tests, mortality count, and fish biomass are carefully recorded enabling a maintained consistent environment.